Rise in penetration of bio-based materials and high-end technological advancements on board fuel the growth of the global 3D printing metal market. On the other hand, high costs related to raw materials restrain the growth to some extent. Nevertheless, rapidly growing industries such as healthcare, automotive, and aerospace & defense are expected to pave the way for lucrative opportunities in for the key players in the industry.

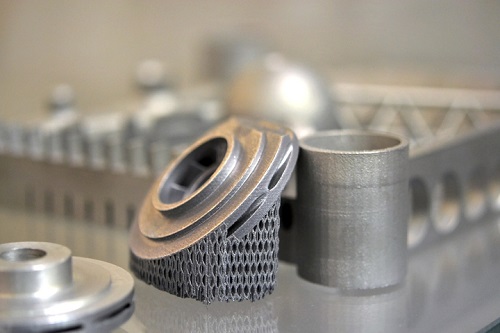

The 3D printing metal industry, also known as metal additive manufacturing or metal 3D printing, has been rapidly evolving in recent years. This technology involves the use of various metal alloys and processes to create three-dimensional objects layer by layer.

Request Report Sample @ https://www.alliedmarketresearch.com/request-sample/6447

Here are some key aspects of the 3D printing metal industry:

- Materials: The selection of metal materials is crucial in metal 3D printing. Commonly used metals and alloys include stainless steel, aluminum, titanium, nickel-based superalloys, and precious metals like gold and silver. The choice of material depends on the specific application and desired properties of the final product.

- Processes: There are several different 3D printing processes for metals, including:

- Selective Laser Melting (SLM): This method uses a high-powered laser to selectively melt and fuse metal powder particles layer by layer. It is known for producing dense and strong parts.

- Electron Beam Melting (EBM): EBM employs an electron beam to melt and fuse metal powder. It is often used for aerospace and medical applications.

- Direct Metal Laser Sintering (DMLS): DMLS is similar to SLM but uses a lower-power laser. It’s suitable for smaller, high-precision parts.

- Binder Jetting: This technique involves spreading a layer of metal powder and using a liquid binder to selectively solidify the powder. After printing, the part is sintered to remove the binder and fuse the metal particles.

The aluminum segment contributed to around half of the total market revenue in 2019, and is expected to retain its dominance by the end of 2026. At the same time, the steel segment would project the fastest CAGR of 24.2% during the study period. The other segments assessed in the market report include titanium and nickel.

- Applications:

- Aerospace: Metal 3D printing is widely used in aerospace for creating lightweight, complex components, such as turbine blades and structural parts.

- Medical: It’s used to produce custom implants, orthopedic devices, and dental prosthetics.

- Automotive: The automotive industry uses metal 3D printing for rapid prototyping, custom parts, and lightweight components.

- Tooling: Metal 3D printing is employed for producing molds, dies, and tooling with intricate designs.

The powder segment held nearly three-fourths of the total market share in 2019, and is projected to retain the top status by 2026. The filament segment, on the other hand, is anticipated to manifest the highest CAGR of 24.1% throughout the forecast period.

- Advantages:

- Complex Geometries: Metal 3D printing allows for the creation of highly complex and intricate designs that are difficult or impossible to achieve with traditional manufacturing methods.

- Reduced Waste: Unlike subtractive manufacturing, where material is removed, additive manufacturing generates less waste as it only uses the necessary amount of material.

- Rapid Prototyping: It enables quick iteration and prototyping of designs, saving time and money in product development.

North America generated the highest market share in 2019, holding more than two-fifths of the global market. Simultaneously, the region across Asia-Pacific would register the fastest CAGR of 24.2% by 2026. The other two provinces discussed in the report include LAMEA and Europe.

- Challenges:

- Cost: Metal 3D printing can be expensive due to the high cost of equipment, materials, and post-processing steps like heat treatment and machining.

- Quality Control: Ensuring consistent quality and mechanical properties in printed metal parts can be challenging.

- Size Limitations: The build size of most metal 3D printers is limited, which can be a constraint for large-scale production.

- Future Outlook: The metal 3D printing industry is expected to continue growing as technology improves, costs decrease, and more industries adopt this technology. Research is ongoing to develop new materials and processes for enhanced performance and cost-efficiency.

According to the report published by Allied Market Research, the global 3D printing metal market was estimated at $147.2 million in 2018 and is expected to hit at $796.3 million by 2026, registering a CAGR of 23.5% from 2019 to 2026.

Frontrunners in the industry-

The key market players analyzed in the global 3D printing metal market report include Arcam AB, Autodesk, Inc., 3D Systems, Voxeljet AG, The ExOne Company, Hoganas AB, Optomec, Inc., Ponoko Limited, Stratasys Ltd, and Organovo Holdings, Inc. These market players have incorporated several strategies including partnership, expansion, collaboration, joint ventures, and others to brace their stand in the industry.

Interested in Procuring this Report? Visit Here: https://www.alliedmarketresearch.com/3d-printing-metal-market/purchase-options

𝐀𝐛𝐨𝐮𝐭 𝐔𝐬

Allied Market Research (AMR) is a full-service market research and business-consulting wing of Allied Analytics LLP based in Portland, Oregon. Allied Market Research provides global enterprises as well as medium and small businesses with unmatched quality of “Market Research Reports” and “Business Intelligence Solutions.” AMR has a targeted view to provide business insights and consulting to assist its clients to make strategic business decisions and achieve sustainable growth in their respective market domain.

We are in professional corporate relations with various companies and this helps us in digging out market data that helps us generate accurate research data tables and confirms utmost accuracy in our market forecasting. Allied Market Research CEO Pawan Kumar is instrumental in inspiring and encouraging everyone associated with the company to maintain high quality of data and help clients in every way possible to achieve success. Each and every data presented in the reports published by us is extracted through primary interviews with top officials from leading companies of domain concerned. Our secondary data procurement methodology includes deep online and offline research and discussion with knowledgeable professionals and analysts in the industry.

Contact:

David Correa

United States

1209 Orange Street,

Corporation Trust Center,

Wilmington, New Castle,

Delaware 19801 USA.

Int’l: +1-503-894-6022

Toll Free: +1-800-792-5285

Fax: +1-800-792-5285

Web: www.alliedmarketresearch.com

Allied Market Research Blog: https://blog.alliedmarketresearch.com