Milk is a rich source of and vital nutrients. Milk is produced in large volume all over the world and India is the leading producer of milk globally. The problem with large volumes of milk production is that raw milk can be stored for a maximum of only one week. Effective and efficient cooling is required for storage of milk as it can get spoilt if temperature is not controlled properly. Milk tank cooling systems are of two types – direct expansion milk cooling tank systems and ice bank milk cooling tank systems. Milk tank cooling systems are required to increase the shelf-life of milk and help in its safe transportation.

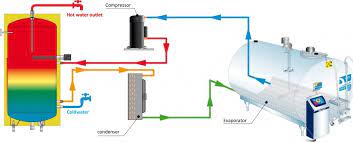

A milk tank cooling system is a system used to cool milk to a safe temperature for storage and consumption. The system typically consists of a cooling unit, a milk storage tank, and a means of circulating the milk between the two. The cooling unit is usually a refrigerator or air conditioner, and the milk storage tank is typically a stainless steel tank.

Request free sample copy of this research study: https://www.alliedmarketresearch.com/request-toc-and-sample/10066

Key Trends

Some of the key trends in milk tank cooling system technology include:

1. Developments in insulation materials: Insulation materials have been constantly evolving and improving, and this has had a major impact on milk tank cooling systems. Newer, more effective insulation materials can help keep milk cooler for longer periods of time, which is essential for maintaining food safety and quality.

2. Improved cooling methods: There have been significant advancements in cooling methods for milk tanks in recent years. Newer methods are more efficient and can better maintain milk at the desired temperature.

3. Automation: Automation is playing an increasingly important role in milk tank cooling systems. Automated systems can help reduce labor costs and improve efficiency.

4. Energy efficiency: Energy efficiency is a major focus for many manufacturers of milk tank cooling systems. Newer, more efficient systems can help reduce energy costs and improve sustainability.

Key Drivers

The key drivers of Milk Tank Cooling System market are efficiency, reliability, and easy to operate. The Milk Tank Cooling System is easy to operate with the help of a simple user interface. The Milk Tank Cooling System is designed to be efficient and reliable.

Get Customized Report as Per Your Requirement: https://www.alliedmarketresearch.com/request-toc-and-sample/10066

Market Segmentation

The Milk Tank Cooling System Market is segmented by type, configuration, industry vertical, and region. By type, the market is classified into direct expansion system tank and ice bank tank and others. By configuration, the market is bifurcated into open milk tank, fully enclosed milk tank, and others . By industry vertical, the market is divided into food, FMCG, cold storage and others. By region, the market is segmented into North America, Europe, Asia-Pacific and rest of the world.

Key Players

The key players in the Milk Tank Cooling System Market are GEA Group AG, DeLaval, Dairymaster, Packo Cooling, Serap Group, Boumatic, Fabdec, Wedholms AB, Fic Spa and Milkplan.