Deep hole drilling machines are precision machines used for the drilling of deep and precise holes in a variety of materials such as metal, plastic, and wood. The global deep hole drilling machines market is expected to witness significant growth in the coming years, driven by factors such as the growth of the aerospace and defense industries, increasing demand for high-precision drilling, and advancements in drilling technologies.

𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭 : https://www.alliedmarketresearch.com/request-sample/7539

Market Size and Growth

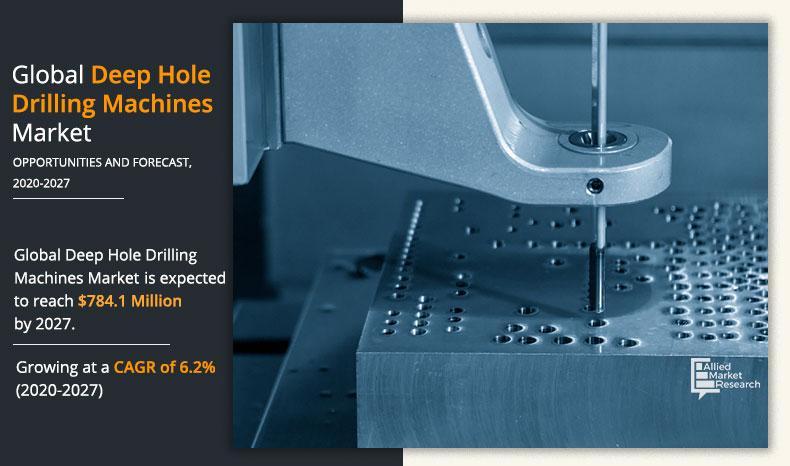

According to a report by Allied Market Research, deep hole drilling machines market size was valued at $611.1 million in 2019 and is projected to reach $784.1 million by 2027, registering a CAGR of 6.2% from 2020 to 2027. The market is driven by factors such as the increasing demand for deep hole drilling machines in the aerospace and defense industries, the growing demand for high-precision drilling in the automotive and medical industries, and advancements in drilling technologies.

Types of Deep Hole Drilling Machines

There are several types of deep hole drilling machines available in the market, including:

Gun Drilling Machines: These are commonly used for drilling holes with diameters ranging from 1mm to 50mm and depths up to 2,000mm. They are used in the aerospace, defense, and medical industries.

BTA Drilling Machines: These are commonly used for drilling holes with diameters ranging from 20mm to 250mm and depths up to 20,000mm. They are used in the automotive and energy industries.

Skiving and Roller Burnishing Machines: These machines are used for creating a smooth and precise finish on the inside of deep holes. They are commonly used in the hydraulic and pneumatic industries.

𝐁𝐮𝐲 𝐓𝐡𝐢𝐬 𝐑𝐞𝐩𝐨𝐫𝐭 : https://www.alliedmarketresearch.com/checkout-final/5ece05a293ae3f4d18218e13560d09c7

Applications of Deep Hole Drilling Machines

Deep hole drilling machines are used in a wide range of applications, including:

Aerospace and Defense: Deep hole drilling machines are commonly used in the aerospace and defense industries for the drilling of holes in aircraft components, such as landing gear, turbine blades, and engine parts.

Automotive: Deep hole drilling machines are also used in the automotive industry for the drilling of holes in engine blocks, crankshafts, and other engine components.

Medical: Deep hole drilling machines are used in the medical industry for the drilling of holes in surgical instruments and orthopedic implants.

Regional Market Analysis

The global deep hole drilling machines market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East and Africa. Asia-Pacific is expected to dominate the market during the forecast period, driven by the increasing demand for deep hole drilling machines in the automotive, aerospace, and defense industries in countries such as China and India.

North America and Europe are also expected to witness significant growth in the deep hole drilling machines market during the forecast period, driven by factors such as the increasing demand for high-precision drilling in the aerospace and defense industries, and advancements in drilling technologies.

𝐏𝐮𝐫𝐜𝐡𝐚𝐬𝐞 𝐄𝐧𝐪𝐮𝐢𝐫𝐲 : https://www.alliedmarketresearch.com/purchase-enquiry/7539

Competition Analysis

The key market players profiled in the report include Entrust Manufacturing Technologies, Inc., HONG JI Precision Machinery Ltd., Hochent (Shanghai) Machinery Development Co., Ltd. (HTT), KGD. Co., Ltd. (Korea Gundrill), I.M.S.A. S.r.l., Mollart Engineering Limited, TBT Tiefbohrtechnik GmbH + Co., TIBO Tiefbohrtechnik GmbH, Cheto Corporation S.A., Galbiati Costruzioni Meccaniche S.r.l., Loch Präzisions Bohrtechnik GmbH, Kennametal Inc., (WIDMA- Machining Solutions Group), Frankor Hydraulics, Precihole Machine Tools, and Kays Engineering, Inc.

In conclusion, the global deep hole drilling machines market is expected to witness significant growth in the coming years, driven by factors such as the growth of the aerospace and defense industries, increasing demand for high-precision drilling, and advancements in drilling technologies. With the advent of new technologies and innovative designs, deep hole drilling machines are expected to continue to evolve, providing efficient and precise drilling solutions for a range of industries. As the demand for sustainable and eco-friendly drilling solutions increases, manufacturers are expected to focus on developing eco-friendly and sustainable deep hole drilling machine designs and technologies to meet the evolving needs of the market.